In-Mold Decorations in Modern Manufacturing: A Comprehensive Guide

In-Mold Decorations in Modern Manufacturing: A Comprehensive Guide

Blog Article

Mastering In-Mold Decorations: Approaches, Fads, and Finest Practices for Optimal Results

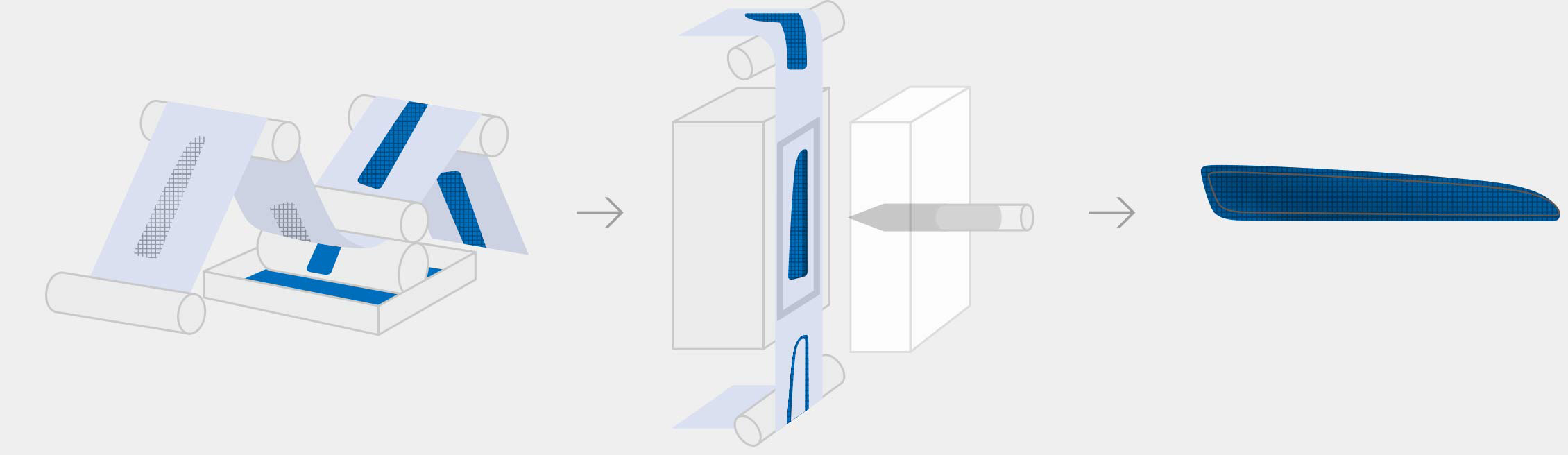

In the world of manufacturing, the art of in-mold designs stands as a crucial aspect of product design and production. In-Mold Decorations. By diving right into the methods, trends, and best practices that underpin effective in-mold decor procedures, businesses can unlock a realm of opportunities that not just elevate the visual attraction of their products yet additionally enhance manufacturing efficiency and bolster customer interaction.

Material Option

Material choice is an essential aspect of grasping in-mold decors, as it directly impacts the high quality and longevity of the last product. When selecting materials for in-mold decors, it is necessary to take into consideration elements such as compatibility with the molding process, the desired aesthetic outcome, and the ecological problems the item will certainly encounter.

Furthermore, materials with high warm resistance are favored for in-mold designs, specifically for items that will be revealed to raised temperature levels throughout their lifecycle. By very carefully picking the ideal product for in-mold designs, manufacturers can improve the overall quality and durability of their products, satisfying the expectations of both end-users and customers - In-Mold Decorations.

Layout Development

An essential variable in progressing the field of in-mold designs is the continuous exploration and application of design innovation strategies. Design technology plays a critical role in enhancing the visual allure, performance, and total high quality of products produced using in-mold design processes. By integrating ingenious style components, producers can distinguish their products on the market, bring in customers, and stay ahead of competitors.

Among the crucial elements of style innovation in in-mold decors is the integration of intricate patterns, structures, and graphics that were previously testing to achieve with typical decor approaches. Advanced innovations such as 3D printing and digital layout devices make it possible for developers to create complex and in-depth layouts that can be flawlessly transferred onto shaped parts. Furthermore, the use of vivid colors, metallic finishes, and unique effects like gloss or matte appearances can even more raise the aesthetic allure of in-mold embellished products.

Additionally, style development extends past looks to incorporate useful enhancements such as ergonomic shapes, integrated functions, and adjustable components that satisfy details customer requirements. By welcoming design innovation, suppliers can unlock brand-new opportunities for product, personalization, and creative thinking differentiation in the affordable landscape of in-mold decorations.

Manufacturing Performance

Reliable production procedures are important for translating the innovative styles developed in the field of in-mold decorations right into top quality completed items that meet market demands and customer assumptions. In the world of in-mold decorations, production effectiveness encompasses numerous essential elements that add to the total success of the production process. One vital aspect is the optimization of mold and mildew layout and tooling to make certain smooth and precise decor transfer onto the end product. By fine-tuning mold and mildew configurations and buying top notch tooling products, manufacturers can improve efficiency and uniformity in manufacturing.

Furthermore, implementing automation and robotics in the manufacturing line can significantly boost effectiveness by simplifying repeated tasks and lowering the margin of mistake. Automation not only accelerates the manufacturing procedure yet also enhances precision and repeatability, resulting in an extra high-quality and uniform end product. Moreover, taking on lean manufacturing principles, such as just-in-time supply monitoring and waste decrease techniques, can even more enhance manufacturing effectiveness by lessening downtime and maximizing source application. Overall, a holistic approach to production efficiency is vital in making best use of the potential of in-mold decoration methods and attaining optimal lead to the open market landscape.

High Quality Control Actions

What are the essential approaches for guaranteeing stringent top quality control actions in the realm of in-mold decorations? Quality control actions are paramount in in-mold decor processes to ensure the production of perfect and home top quality ended up products.

Using advanced innovations such as automatic inspection systems can likewise improve the quality control procedure by supplying precise and trusted information for evaluation. These systems can discover imperfections that may be missed by hand-operated evaluations, therefore improving total item high quality and consistency.

Regular training and growth programs for staff members included in the in-mold design procedure can additionally add to keeping high-quality criteria. By educating team on ideal practices, high quality assumptions, and the relevance of interest to detail, firms can cultivate a culture of top quality consciousness throughout the company.

Consumer Charm

To improve the marketability of in-mold decoration products, understanding and catering to consumer preferences play an essential role in identifying their appeal and success. Consumer allure in in-mold designs is influenced by different factors, including layout looks, color selections, longevity, my website and overall functionality. Customers are increasingly seeking customized and one-of-a-kind products that show their uniqueness and design. As a result, using personalization alternatives such as customized designs, shade variants, and textural aspects can dramatically enhance the allure of in-mold decor products.

Conclusion

In-mold decors provide a effective and versatile method to improve item aesthetic appeals. By meticulously selecting materials, welcoming ingenious styles, maximizing manufacturing processes, executing quality assurance actions, and prioritizing customer allure, producers can accomplish ideal results. It is essential for business to constantly adapt and boost their approaches to stay affordable in the marketplace. In-Mold Decorations. Grasping in-mold designs calls for an alternative approach that considers all aspects of the manufacturing procedure to guarantee success.

In the world of manufacturing, the art of in-mold decors stands as a critical aspect of product design and production. Design advancement plays an essential role in boosting the aesthetic charm, performance, and overall high quality of products made making use of in-mold decoration procedures.One of the key facets of style development in in-mold decorations is the integration of elaborate patterns, structures, and graphics that were previously challenging to accomplish with typical decor methods.Reliable production processes are essential for converting the ingenious designs created in the field of in-mold decorations right into top quality finished products that fulfill market demands and customer expectations. Offering modification alternatives such as personalized designs, color variants, and textural aspects can considerably enhance the appeal of in-mold design items.

Report this page